CAT6e is an augmented specification of CAT6, doubling the frequency from 250 MHz to 600 MHz, enhancing performance for high-speed data transmission. While there’s no official standard, it boosts capabilities for applications like Gigabit Ethernet. It is designed to double the frequency from 250 MHz to 600 MHz.

Understanding Cat6e Cable

Category 6e (Cat6e) cable is a type of standardized twisted pair cable, an augmented version of the Category 6 cable. It’s designed to support faster speeds, like Gigabit Ethernet and 10 Gigabit Ethernet.

Cat6 cables are designed for Gigabit Ethernet. Unless they backward adapt themselves to older Ethernet standards, Cat6 cables use all eight wires⁚ Pairs 1 and 2 for data transmitting and receiving separately, pairs 3 and 4 for additional data transmission and PoE applications.

A standard Cat6 cable consists of four twisted pairs of wires, making a total of eight wires. The wires in a standard Cat6 cable are blue, blue and white, brown, brown and white, green, green and white, orange, and orange and white.

Cat6, or Category 6 cable, is a standardized twisted pair cable for Ethernet and other network physical layers. Its designed to provide up to 10 Gb/s performance and is suitable for up to 250MHz.

Category 6e doubles the transmission frequency to 500MHz and allows for 10Gbps speeds. The data transmission must perform above the TIA limit for up to 250MHz. The cable can extend up to 100 meters and transfer data at a maximum.

Cat6e Specifications and Capabilities

Cat6e cables support data transfer rates of up to 10 Gbps (Gigabits per second), making them suitable for high-bandwidth applications. It also offers more stringent specifications for system noise.

Cat6 cabling standards typically utilize 23-AWG conductor. That .0226 inches in diameter per wire. So what? In terms of area, that .2582 mm. Multiply that by your 48 cables.

The cable can extend up to 100 meters and transfer data at a maximum. The data transmission must perform above the TIA limit for up to 250MHz.

It is designed to double the frequency from 250 MHz to 600 MHz. CAT6e is an augmented specification of CAT6. There is no standard for CAT6e that..;

Category 6 is required for Gigabit Ethernet at 1000Mbps over 100 meters. Category 6e doubles the transmission frequency to 500MHz and allows for 10Gbps speeds. The data transmission must perform above the TIA limit for up to 250MHz.

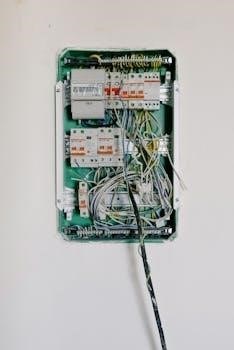

Tools Required for Cat6e Wiring

To effectively wire Cat6e cables, several essential tools are needed. The most basic tool is a cable stripper, which removes the outer jacket of the cable without damaging the inner wires. A crimping tool is also indispensable.

Choose a tool that provides consistent pressure and is compatible with both CAT5e and CAT6 connectors for backward compatibility. A punch-down tool is indispensable for terminating cables on patch panels and wall outlets. It precisely seats individual wires into the correct slots, ensuring…

Use a cable cutter for a clean cut. Measure the required length of the Cat6 cable, adding extra for adjustments. Use a cable stripper to remove 1-2 inches of the outer jacket, exposing the twisted pairs.

Whether it be an 8P8C RJ45 plug, keystone jack, or patch panel this holds true regardless of what kind of termination you are performing. This scheme is designed to help … wires into the right order so that your cable will work properly.

Wiring Standards⁚ T568A vs. T568B

T568A and T568B are standards for wiring Cat5e, Cat6, and Cat6a twisted pair cables. This is a basic rule for the internet backbone infrastructure, internet providers, and network installers to assign the right wiring scheme.

T568A Wiring Scheme

The T568A wiring scheme is a standard that dictates the order in which the eight wires within a Cat6e cable must be arranged when terminating with RJ45 connectors or keystone jacks. This scheme ensures proper connectivity and optimal performance in Ethernet networks. It is designed to help organize wires into the correct order so that your cable will work properly. It is a critical aspect of network infrastructure, ensuring seamless data transmission across connected devices.

The T568A standard specifies a particular sequence of colors for the wires⁚ green/white, orange, green, blue/white, blue, orange/white, brown, and brown/white. Following this sequence precisely is essential for maintaining signal integrity and preventing network issues. Whether terminating an 8P8C RJ45 plug, keystone jack, or patch panel, adhering to this wiring order is crucial. Correct implementation of T568A helps to establish reliable communication links within a network.

T568A wiring scheme is recognized by ANSI/TIA-568-C wiring standards, ensuring compatibility and interoperability in various network environments.

T568B Wiring Scheme

The T568B wiring scheme stands as an alternative standard to T568A, defining a specific arrangement for the eight wires within a Cat6e cable when terminating with RJ45 connectors or keystone jacks. Like T568A, it aims to ensure proper connectivity and optimal performance in Ethernet networks. Both the T-568A and the T-568B standard Straight-Through cables are used most often as patch cords for your Ethernet connections.

The T568B standard prescribes a different color sequence compared to T568A⁚ orange/white, orange, green/white, blue, blue/white, green, brown/white, and brown. Maintaining this specific order is critical for ensuring signal integrity and preventing potential network problems. Adhering to this wiring order is crucial, whether terminating an 8P8C RJ45 plug, keystone jack, or patch panel. Accurate implementation of T568B contributes to establishing dependable communication links within a network.

Like T568A, the T568B wiring scheme is also recognized by ANSI/TIA-568-C wiring standards. You can use either of the configurations for your network cables, so long as you use the same one on both ends of the Cat6 wire.

Choosing Between T568A and T568B

When deploying Cat6e cables, a fundamental decision arises⁚ selecting between the T568A and T568B wiring schemes. While both standards meet ANSI/TIA-568-C requirements, consistency is paramount. The key is that you use the same one on both ends of the Cat6 wire.

In new installations, T568A is often preferred as the default, aligning with established practices. However, existing networks might already utilize T568B. Both T-568A and T-568B configurations have been included in the diagram, as both of them meet ANSI/TIA-568-C wiring standards.

The most important factor is maintaining uniformity throughout the network. Mixing standards within a single network segment can lead to connectivity issues and performance degradation. Therefore, carefully assess the existing infrastructure and choose the standard that ensures consistency. If connecting to an existing network, adhere to its pre-existing standard. If starting fresh, T568A offers a widely accepted starting point; If you require a cable to connect two Ethernet devices directly together without a hub or when you connect two hubs together, you will need to use a Crossover cable instead.

Cat6e Wiring Process

The Cat6e wiring process involves several key steps⁚ measuring and cutting the cable, stripping the jacket, arranging the wires according to the chosen standard (T568A or T568B), and terminating with RJ45 connectors.

Measuring and Cutting the Cable

Accurately measuring and cutting the Cat6e cable is the initial crucial step in the wiring process, ensuring sufficient length for your network installation while minimizing excess cable. Begin by determining the precise distance between the two termination points, whether they are a patch panel and a wall outlet or two directly connected devices. Add extra length to this measurement, typically a few extra feet, to provide flexibility for maneuvering the cable during termination and to accommodate any potential adjustments or future changes in your network setup.

Use a specialized cable cutter designed for network cables to achieve a clean and even cut, preventing damage to the internal wires. Avoid using scissors or other general-purpose cutting tools, as they can crush or deform the cable, potentially affecting its performance. A clean cut ensures that all eight wires are of equal length, facilitating proper insertion into the RJ45 connector during termination.

Remember that the quality of the cut directly influences the overall integrity and performance of your Cat6e cable, so take your time and use the appropriate tools.

Stripping the Cable Jacket

Stripping the cable jacket is a delicate yet essential process in Cat6e wiring, requiring precision to expose the internal twisted pairs without damaging them. Utilize a cable stripper specifically designed for network cables to carefully remove approximately 1 to 2 inches of the outer jacket. Adjust the stripper’s blade depth to avoid cutting into the insulation of the individual wires, as this can compromise signal integrity and lead to network performance issues.

When using the cable stripper, gently rotate it around the cable to score the jacket, then flex the cable at the score to create a clean break. Carefully slide the cut portion of the jacket off the cable, revealing the four twisted pairs within. Avoid using excessive force or pulling too hard, as this can damage the wires or alter their twist rates, which are critical for maintaining Cat6e’s performance specifications.

Inspect the exposed wires for any nicks or cuts in their insulation. If damage is present, re-strip the cable further down to ensure a clean section for termination. A properly stripped cable jacket is crucial for successful and reliable Cat6e wiring.

Arranging Wires According to Standard

Arranging the wires according to a specific standard, either T568A or T568B, is paramount for ensuring proper Cat6e cable functionality. Both standards dictate the precise order in which the eight color-coded wires must be positioned within the RJ45 connector. Consistency is key; the same standard must be used on both ends of the cable to establish a straight-through connection, commonly used for connecting devices to a network.

Begin by untwisting the exposed wire pairs, carefully separating them to facilitate arrangement. Straighten each wire individually, ensuring they are free from kinks or bends. Following the chosen standard (T568A or T568B), arrange the wires in the correct sequence. Double-check the order against a reliable wiring diagram to avoid errors.

Once the wires are aligned, maintain their order by holding them firmly between your fingers. Trim the wires to a uniform length, typically around 0.5 inches, using a specialized wire cutter. This ensures that all wires make proper contact with the pins inside the RJ45 connector. The accuracy of this arrangement directly impacts the cable’s ability to transmit data effectively.

Cat6e Wiring Process

Terminating with RJ45 Connectors

Terminating Cat6e cables with RJ45 connectors is a critical step that demands precision and care. After arranging the wires according to the chosen T568A or T568B standard, carefully insert them into the RJ45 connector. Ensure that each wire is fully seated and reaches the end of the connector, maintaining the correct color sequence.

Using a crimping tool designed for RJ45 connectors, firmly crimp the connector to secure the wires in place; The crimping process forces the connector’s pins through the insulation of each wire, establishing a reliable electrical connection. Apply consistent pressure during crimping to guarantee a solid and lasting termination.

Inspect the terminated connector to verify that all wires are properly seated and that the crimping is secure. Gently tug on each wire to ensure it is firmly held in place. A poorly terminated connector can lead to connectivity issues and data loss. If any issues are detected, re-terminate the connector to ensure optimal performance. It is important to use a tool that provides consistent pressure.